Use of innovative technologies and processes

State-of-the-art prefabrication and final assembly ensure short lead times and smooth processes while fulfilling stringent customer requirements.

RMT offers extensive vertical integration in handling customer orders. All production processes are undertaken in-house – from receiving incoming goods and cutting to size through to welding processes, surface treatment and acceptance testing of components. The result is appropriate expertise in processes and methods; this provides customers with maximum quality, productivity and reliability. This coupled with extensive flexibility and customisation means we are also equipped to meet stringent customer requirements. Permanent further development of technologies and processes ensure highly complex installations and systems are built to a maximum quality standard in an extremely short time. The core of this philosophy is a highly qualified, motivated team combined with state-of-the-art resources.

The right solution for every challenge

RMT specialises in the prefabrication and construction of large modules and components. This reduces the working times at the customer’s site, increases quality and minimises costs. Even complete compact stations can be fully pre-equipped with pipeline systems, steel structures, electrical and control technology or heating systems on site and, if required, tested as per the applicable regulations. Only the modules and stations are integrated on the construction site with sharply reduced installation times.

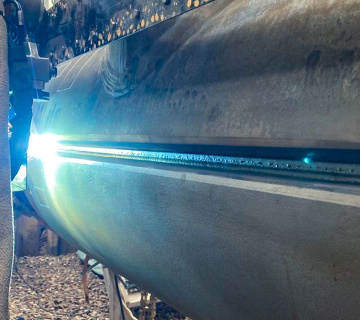

Welding technology

The use of automatic 3D plasma cutting centres with a direct CAD/CAM connection, innovative, mechanised welding technologies and special process know-how means things take less time, errors are reduced and, consequently, savings are made on costs.

Drilling and stoppling

Drilling and stoppling high-pressure gas pipes when installations are in operation requires a high level of expertise and experience. RMT has mastered this effective special technology confidently with no outside assistance for more than 20 years.

Digitisation in production

Production processes are planned, controlled and analysed centrally with self-developed software solutions. Programmes for managing material logistics or tools for pipe log and certificate management ensure maximum transparency, control and performance. RMT is able to evaluate and indicate current project statuses at all times – whether for in-house production planning and control or regular customer reporting.

These tools can be accessed at any time using a tablet, thus essentially ensuring a paperless production process. Barcode systems are used to create a direct link between the system and components and construction progress.

Shaping a pioneering future

We will also continue to develop and optimise our processes and methods in the future to make production and assembly of installations and systems even more efficient. RMT puts innovations and technical expertise into active use.

RMT product developments:

- Development of an inline gas heating process to eliminate CO2 in gas installation systems

- Development and construction of a mobile repair blower for service operations

- Development and implementation of a gas consumption metering system to provide central, error-free recording of total consumption